The severe temperature rise during the injection molding process can have several possible causes. Here are some common factors that may contribute to the temperature rise issue:

1. Cooling system problems: If the cooling system, such as water chillers or cooling pipes, is clogged, leaking, or not functioning properly, it can result in inadequate cooling and lead to temperature rise.

2. Excessive injection speed: When the injection speed is too fast, the flowing molten material can encounter resistance, causing frictional heat generation and an increase in temperature.

3. High injection pressure: If the injection pressure is set too high, it can increase the friction between the molten material and the mold, leading to excessive heat generation.

4. Material degradation: Certain materials are prone to degradation at high temperatures, producing gases and other by-products that can cause temperature rise issues.

5. Non-uniform mold temperature: If the mold temperature is uneven, with certain areas being excessively hot, it can result in localized overheating of the molten material.

6. Incorrect injection machine parameters: Improper settings of temperature, pressure, and speed parameters on the injection machine can contribute to the temperature rise problem.

If you are experiencing severe temperature rise during the injection molding process, consider taking the following actions:

1. Check the cooling system for proper operation and perform maintenance if necessary.

2. Adjust the injection speed and pressure to ensure appropriate filling conditions.

3. Ensure that the material is not degrading by checking its quality or adjusting the temperature settings.

4. Verify the uniformity of mold temperature and make adjustments to the mold temperature control or consider using a more suitable mold.

5. Double-check the injection machine parameter settings to ensure they align with the process requirements.

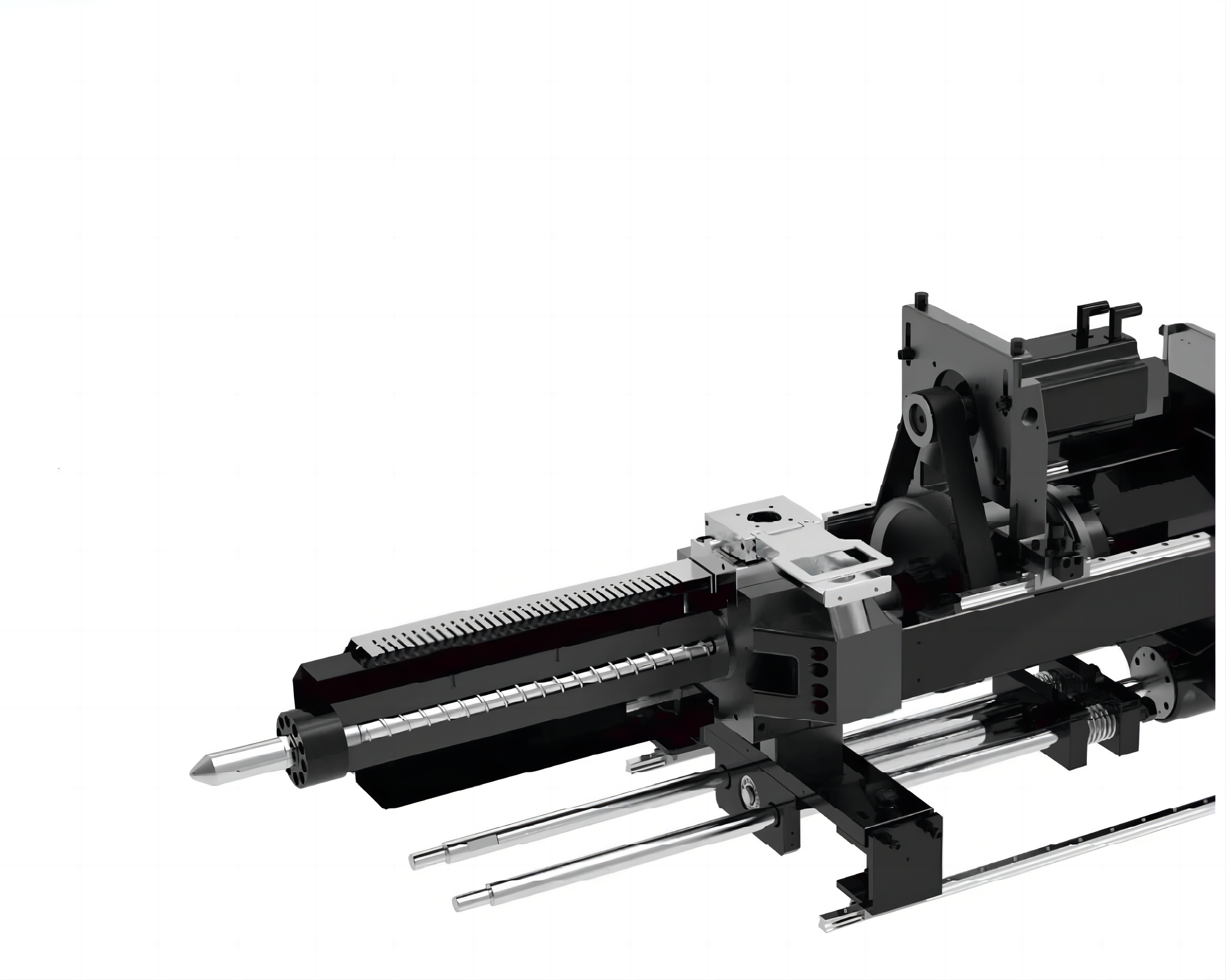

Wear-resistant Screw in bimetallic spraying proc

Screws and Tip Accessories With new TiN and TiAI

Injection molding screws after our polishing pro

Contact: Richard Wang

Phone: 15372657153

Tel: +86-15372657153

Email: info@tokindustry.com

Add: No.1807, R&D Park C Zone -12, Guanghua Road, Hi-Tech District, Ningbo, China

We chat