Specification: Φ15-Φ300 L/D Ratio =10-56 Base Materials: SACM645,SCM440 Treatment: Chromed,Hardned & Bimetallic Delivery Time: 20-25 days 12 Months guarantee after shipment

200$-9000$

General Single Extrusion Screw Mixer & Barrels Types:( 12 Months Guarantee )

Materials & Treatments:

⁕Bimetallic Process :

Basis Materials: SACM645, SACM440, SKD61, SKD11

Hardness: 53-58 HRC

Coating Thickness: 1.5-2.0mm

Allication: Plastic Recycling ≤2 Times, Plastics With Glass Fiber≤35%

Wear resistance: ★★★★★

Corrosion resistance: ★★★

Basis Materials: SACM645, SACM440, SKD61, SKD11

Chrome Thickness: 0.02-0.08mm

Hardness of Chrome: >700 HV

Finish Grade: Ra ≤0.4

Allication: PVC and other high corrosive plastics

Wear resistance: ★★

Corrosion resistance: ★★★★★

⁕Full Hardened Process:

Basis Materials: DC53, D2, M2, SKD61, SKD11 ...

Chemical Composition: C, Si, Cr, Mn, Mo, V, Ni

Hardness: SKD61(HRC56-58), DC53( 62-63 HRC)

Application: PP PA LCP, POM, PPA, PBT, PC, PPS, PEI, PEEK with Glass Fiber ≤50%

Wear resistance: ★★★★★

Corrosion resistance: ★★★★★

![]()

FAQS:

Q: When will you arrange the production?

A: We can arrange the production after order & drawings confirmation

Q: What is your factory delivery time ?

A: Standard delivery time is 20-25 days, if the screw's diameter is less than 50mm, the delivery time will be faster to 15-20 days, also we usually have stock items ready to ship out.

Q: What is your accepted payment type?

A: T/T

Q: What logistic forwarder do you usually work with?

A: We work with UPS, TNT, FEDEX, SF and other logistric forwarders. Assigned your own forwarder for shipment is available.

Q: What is your warranty Time ?

A: Our warranty time is 12 months when shipment on board

![]()

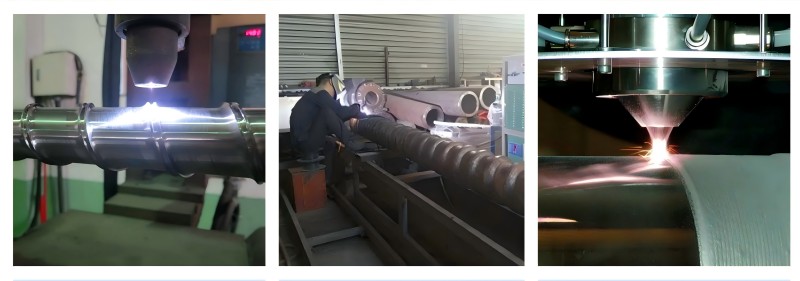

Wear-resistant Screw in bimetallic spraying proc

Screws and Tip Accessories With new TiN and TiAI

Injection molding screws after our polishing pro

Contact: Richard Wang

Phone: 15372657153

Tel: +86-15372657153

Email: info@tokindustry.com

Add: No.1807, R&D Park C Zone -12, Guanghua Road, Hi-Tech District, Ningbo, China

We chat